Providing that the interlock is anaerobic, and this is shown inside the incubator by a large neon indicator the Petri dishes can be removed from the incubator by placing them back into the interlock through the interlock inner door, this door is then closed and the outer door is opened and the dishes are taken out of the interlock.

The interlock is once again aerobic

The Single Plate Entry tunnel

Sometimes it is necessary for an operator to insert just a single Petri dish into the incubator.

This can be in a hospital late at night when an operator unfamiliar with the workstation is required to insert a single plate into the incubator.

The small single plate entry door is quickly opened and the single plate is pushed into the incubator and the door quickly closed.

Note the design, here the single plate entry tunnel is fitted with a hinged door at the back to prevent excessive escape of gas and a ramp that removes and then replaces the Petri dish lid whilst it is being inserted into the incubator. The lifted lid allows the escaping anaerobic gas to blow out the unwanted oxygen trapped beneath the Petri dish lid.

Secondly, the inside of the incubator is held at a positive pressure of 100 Pascals to prevent any oxygen getting into the unit, therefore gas escapes from the incubator during the small time that the single plate entry door is open, prevents any oxygen penetration.

This single plate entry system is a major gas saver for the insertion of a small numbers of dishes.

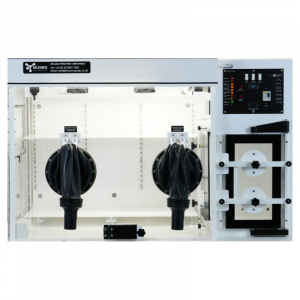

The Gauntlets

The MUNRO(Electrotek) workstation can be used with bare hands with detachable cuffs that are attached to the gauntlets forming the gas seal around the wrists,

Some operators are sensitive to the latex in the standard wrist cuffs and here we can supply neoprene cuffs to overcome this problem.

These neoprene cuffs are much more expensive and much less flexible.

Some applications require glove working within the incubator and here flexible gloves can be attached to the gauntlets in the usual manner.

The Bubble Bottle

A bubble bottle is fitted to the endplate of the incubator, this bottle has three functions.

1) It allows the arms to be inserted into the incubator

2) It allows the low internal gas pressure to be maintained

3) It acts as a safety valve for the incubator in the event of the Mixed Gas inlet solenoid remaining open.

Gas leaks

Once the workstation passes its inspection there should be no gas leaks, however these will occur during its working life.

If the gas leak is serious then the cabinet will sense the fault and close the inlet mixed gas solenoid after a period of 2 minutes of continuous gas flow.

A neon indicator on the control panel shows the problem and a buzzer is activated.

Unless the mixed gas solenoid is closed down the whole cylinder of gas would be emptied into the laboratory

This kind of leak is usually caused by the operator not checking the water level in the Bubble Bottle over a lengthy period, but is very easily cured by adding more water to the bottle.

The other causes of a gas leak are a damaged gauntlet or cuff or a damaged door seal.

These are the things to check during a routine maintenance visit.

The O Rings attaching the gauntlet assemblies together are affected by sunlight and show cracks on their surface. At this stage the O Rings should be replaced.