When working with materials that break down when exposed to oxygen, anaerobic workstations make sure there is no oxygen in the air.

Anaerobic workstations: These are stations that regulate the atmosphere. In a laboratory, when one works with components that break down when exposed to oxygen, anaerobic stations are made use.

Anaerobic jars: It is one of the instruments that is used in producing an environment that is anaerobic.

Comparison between the Anaerobic chamber and Anaerobic jars:

Anaerobic jars:

When a laboratory makes use of anaerobic jars, a completely anaerobic environment cannot be maintained. This is due to the possibility of leakages. Along with this, there is no chance of inspection of culture plates that are present in the anaerobic jars. This causes frequent disturbances in the anaerobic environment in the laboratory. Not only this, but it’s also costly to work with anaerobic jars in laboratories with a high anaerobic workload since they demand a lot of incubator area.

Anaerobic workstations:

These workstations prove to be more beneficial than the anaerobic jars as they provide better anaerobic conditions along with greater accuracy. These stations boost the rate of isolation of anaerobic pathogens, and they do not require disrupting the incubation. They can be examined as per demand without the anaerobic conditions being altered. They come at a much low expense than anaerobic jars too.

Ensure your workstation should have these:

- The ease with the samples and operator entering and exiting the workstation is also a crucial point to note. This ensures that not too much disruption occurs to the anaerobic environment during entry and exit. After incubation, transferring of plates occurs. During this process, there is a possibility of oxygen exposure, so even this is to be kept in mind, and easy access to the workspace should be kept in mind.

- Frequent monitoring of the workstation should be done. This includes checking of its temperature, anaerobic conditions, humidity, and all other factors.

- As per the need of the laboratory, the architecture of the workstation fits your requirements accordingly. The size should be accurate, along with the amount of usable area it provides and the layout.

Use of anaerobic workstation’s chambers:

The anaerobic chamber was created to be used in microbiology. With changing times, it has changed to fulfil the demands of its operators and continues to be an important tool used in laboratories. The anaerobic chamber is often used in investigations on organic matter, biofuels, biomass, and bioremediation, and also in the field of drug discovery and to identify contagious diseases.

Best anaerobic chambers

1.

Anaerobic Chamber/Workstation- 4 Gloves,800 Petri Dishes

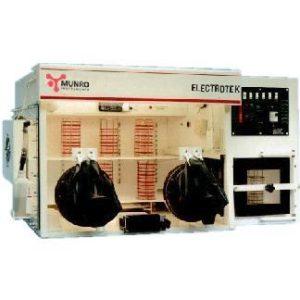

The AW800TGRF4P is the largest workstation in the Electrotek range. One of the main advantages of the

unit is that despite its large capacity, it only occupies a modest amount of bench area. The workstation is

very economical to run, as two gas supplies are used.

2.

Anaerobic Chambers-2 Gloves,400 Petri Dishes

his range of workstations is ideal for the laboratory where oxygen free conditions are required for the

growth and identification of bacteria. The careful configuration gives the units a small bench area

yet ample working room within the incubator

3.

Anaerobic Workstation-2 Gloves,220 Petri Dishes

The AW200SG is the smallest of MUNRO’s range of anaerobic workstations. It is ideal for the laboratory

where oxygen free conditions are required for the growth and identification of bacteria.