A laboratory glove box is a sealed container with built-in gloves that allow the user to manipulate objects inside the box without exposing them to the external environment. This controlled environment helps prevent contamination and protects both the operator and the materials being handled.

Laboratory glove boxes are indispensable tools in scientific research, enabling researchers to work with highly reactive substances, toxic chemicals, and sensitive materials with precision and safety. They provide a barrier between the user and the materials, minimizing the risk of exposure and contamination.

Types of Laboratory Glove Boxes

Laboratory glove boxes come in various types, each designed for specific applications and requirements.

Isolation Glove Boxes

Isolation glove boxes are designed to provide a barrier between the user and the materials inside the box. They are often used when handling hazardous or infectious materials that pose a risk to the operator or the environment.

Controlled Atmosphere Glove Boxes

Controlled atmosphere glove boxes are equipped with systems to regulate the internal environment, including temperature, humidity, and gas composition. They are commonly used in research involving sensitive materials that require a specific atmosphere for processing or analysis.

Combination Glove Boxes

Combination glove boxes combine features of isolation and controlled atmosphere glove boxes, offering both a barrier against external contaminants and control over the internal environment. They are versatile tools suitable for a wide range of research applications.

Components-General

Laboratory glove boxes consist of several key components that work together to provide a controlled environment for handling materials.

Glove Ports

Glove ports are openings in the glove box walls equipped with gloves that allow the user to reach inside the box while maintaining a sealed environment. They are typically made of durable materials such as rubber or neoprene and are designed to provide a comfortable fit for the user’s hands.

Gas Purification Systems

Gas purification systems remove impurities from the internal atmosphere, ensuring a clean and controlled environment inside the glove box. These systems often include filters and scrubbers to remove contaminants such as moisture, oxygen, and volatile organic compounds.

Pressure Control Systems

Pressure control systems maintain the desired pressure inside the glove box, preventing leaks and ensuring a stable environment for sensitive materials. They may include mechanisms such as vacuum pumps or pressure regulators to adjust the internal pressure as needed.

Transfer Chambers

Transfer chambers allow materials to be safely introduced into or removed from the glove box without compromising the integrity of the internal environment. They typically feature airlocks or pass-through ports that prevent contaminants from entering the glove box during transfer operations.

Choosing the Right Laboratory Glove Box

Selecting the right laboratory glove box depends on various factors, including the specific research needs, budget considerations, and manufacturer reliability.

Research Needs and Requirements

Before purchasing a laboratory glove box, it’s essential to evaluate the specific research needs and requirements. Consider the types of materials to be handled, the level of control required over the internal environment, and any special features or capabilities needed for the research.

Budget Considerations

Laboratory glove boxes vary widely in cost, depending on factors such as size, features, and quality. It’s essential to establish a budget and prioritize features based on their importance to the research objectives.

Applications of Laboratory Glove Boxes

Laboratory glove boxes find applications in a wide range of industries and research fields, including pharmaceuticals, electronics, and chemical synthesis.

Pharmaceutical Research

In pharmaceutical research, They are used to handle sensitive materials such as active pharmaceutical ingredients (APIs), drug formulations, and controlled substances with precision and safety.

Battery Manufacturing

Laboratory glove boxes are in important in battery manufacturing processes, providing a controlled environment for assembling battery components, handling electrolytes, and conducting quality control tests.

Electronics Assembly

In electronics assembly operations, They are used to protect delicate electronic components from contamination and moisture during soldering, assembly, and testing processes.

Chemical Synthesis

Laboratory glove boxes are indispensable tools in chemical synthesis laboratories, enabling researchers to work with air-sensitive or moisture-sensitive reagents and intermediates under controlled conditions.

what are ACRYLIC LABORATORY GLOVE BOXES

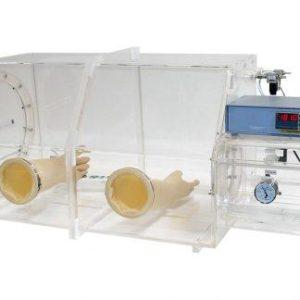

Acrylic laboratory glove boxes are enclosed containers used in scientific research settings to provide a controlled environment for handling materials that require protection from contamination or exposure to external elements. These boxes are typically made of transparent acrylic material, allowing researchers to observe and manipulate the contents inside while maintaining a barrier between the user and the materials.

The primary purpose of acrylic laboratory glove boxes is to create a controlled atmosphere that prevents contamination of sensitive materials, such as chemicals, biological samples, or electronic components. They are often equipped with built-in gloves attached to the box, allowing researchers to manipulate objects inside without compromising the sterile environment.

How do glove boxes help maintain a controlled environment in laboratory settings?

Glove boxes are enclosed, controlled environments commonly used in laboratory settings to handle materials that are sensitive to air or moisture, or to work with hazardous materials safely. They typically consist of a transparent or translucent chamber made of materials like acrylic or polycarbonate, equipped with gloves built into the sides or front to allow the operator to manipulate objects inside without exposing them to the external environment.

What safety features should one consider when selecting a laboratory glove box?

- Material Compatibility: Ensure the glove box materials are compatible with the substances being handled inside. Different chemicals may react with certain materials, leading to contamination or compromised safety.

- Glove Material: The gloves should be made from durable materials such as butyl, neoprene, or latex, depending on the chemical resistance required. They should also fit comfortably and allow for dexterity to handle delicate operations.

- Inert Atmosphere: Many glove boxes provide an inert atmosphere, typically using gases like nitrogen or argon, to prevent reactions with oxygen-sensitive materials. Make sure the glove box maintains the desired atmosphere consistently.

- Air Filtration System: An effective air filtration system is essential for maintaining a clean and safe working environment inside the glove box. This system should remove contaminants and particulates to prevent contamination of experiments and protect personnel.

- Pressure Control: The glove box should allow for precise control of internal pressure to prevent leaks and maintain containment. Pressure monitoring systems can help ensure safe operating conditions.

- Leak Detection: Incorporating leak detection systems ensures that any breaches in the glove box’s integrity are promptly identified, minimizing risks of exposure to hazardous materials.

- Emergency Stop Mechanism: A clearly labeled emergency stop mechanism should be easily accessible to quickly shut down glove box operations in case of emergencies or malfunction.

- Access Ports and Interlocks: Access ports with interlocks help prevent accidental exposure to hazardous materials by ensuring that the glove box can only be accessed when it is safe to do so.

- Fire Suppression System: In case of fire or ignition within the glove box, a fire suppression system can quickly extinguish flames to prevent spreading and minimize damage.

- User Training and Safety Procedures: Comprehensive user training and clear safety procedures are essential for the safe operation of a glove box. Users should be educated on proper handling techniques, emergency protocols, and the potential hazards associated with the materials being used.

- Ergonomic Design: A well-designed glove box should consider ergonomic factors to minimize user fatigue and discomfort during prolonged use, thereby reducing the likelihood of accidents.